Menu

Nalu Canoes proudly presents the finest fitting outrigger canoes, tailored to enhance your performance, whether you’re a beginner, experienced, or professional paddler! Explore our exceptional collection.

Nalu Canoes proudly presents the finest fitting outrigger canoes, tailored to enhance your performance, whether you’re a beginner, experienced, or professional paddler! Explore our exceptional collection.

Our advanced manufacturing process, backed by computer software and technology, guarantees 100% accuracy in tooling. Experience the artistry behind the canoes as they undergo vacuum-bagging and autoclaving, resulting in superior bonding and unbeatable performance.

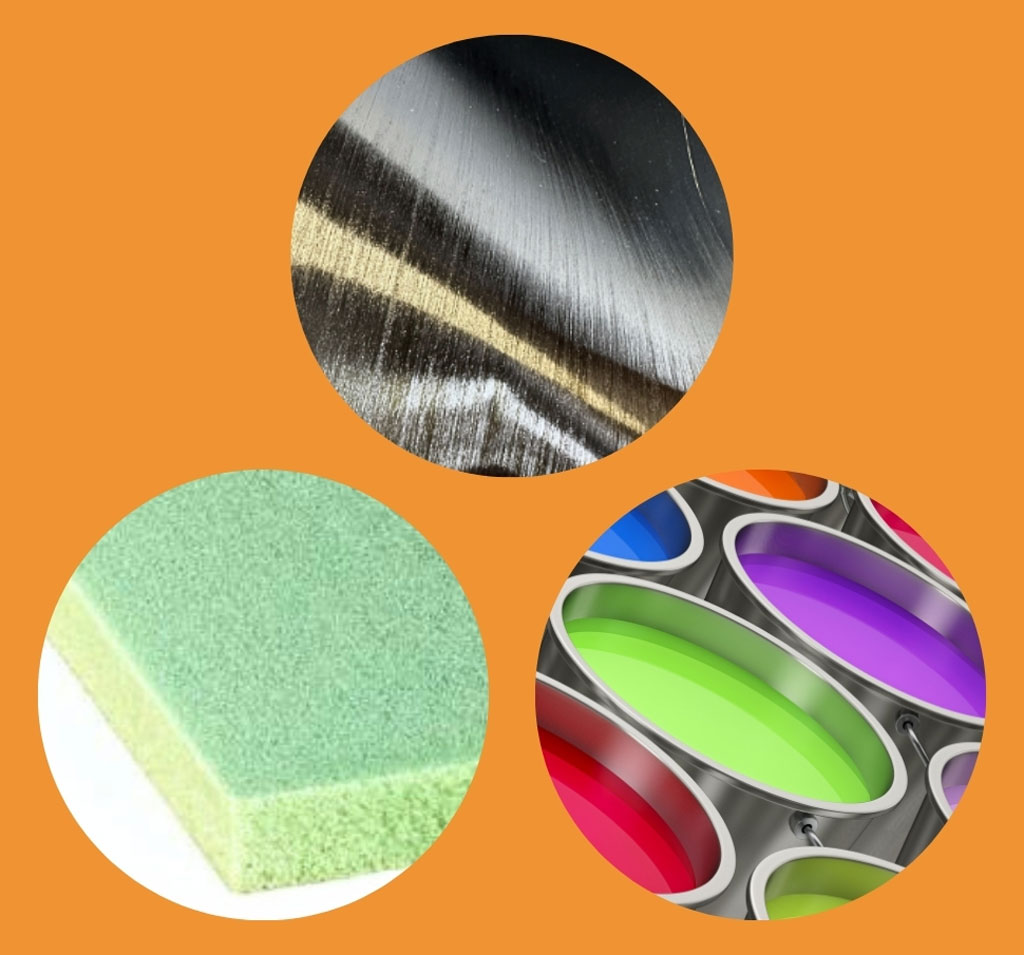

Crafted with the utmost precision, our canoes are built using the finest materials available. We employ cutting-edge prepreg carbon fiber and high-density PVC foam cores to ensure lightweight yet sturdy structures. Explore the quality materials that make our canoes exceptional.

Collaborating with the best in the industry, our partners play a vital role in shaping the excellence of Nalu Canoes. Together, we share a commitment to innovation, quality, and the pursuit of perfection.

bekayak.com

bumbyak.com

paddlesportsireland.com

opadvantage.net

paddlerhq.com.au

nordickayaksthailand

Our trusted network of dealers brings Nalu Canoes closer to you. With dedication and expertise, they connect paddlers with our exceptional outrigger canoes worldwide. Explore our network of authorized dealers.

Founded in 2007 by Marton Buday, NALU Canoes is the result of his lifelong passion for water sports. From sprint canoeing victories to international races, his journey led him to outrigger canoeing. With a background in technical product design, he crafts high-tech canoes that embody innovation and excellence.

Founded in 2007 by Marton Buday, NALU Canoes is the result of his lifelong passion for water sports. From sprint canoeing victories to international races, his journey led him to outrigger canoeing. With a background in technical product design, he crafts high-tech canoes that embody innovation and excellence.

Explore the Nalu Canoes shop, your ultimate destination for exceptional gear, accessories, and merchandise. Discover the perfect paddling essentials to fuel your next adventure.

Explore the Nalu Canoes shop, your ultimate destination for exceptional gear, accessories, and merchandise. Discover the perfect paddling essentials to fuel your next adventure.

Stay updated with the latest happenings in the world of outrigger canoes. Dive into our News section for insightful articles, product updates, and exciting stories that inspire your waterborne adventures.

Join our canoe community and never miss an update. Subscribe to our newsletter for exclusive insights, special offers, and news. Be the first to know, and stay connected with Nalu Canoes.

OC1 OC2 Outrigger Canoes

NALU CANOES Germany

Winckelmannstr 21., 42287 Wuppertal

Phone No: +49 172 2495502

Email: info@nalucanoes.com

OC1 OC2 Outrigger Canoes

NALU CANOES Germany

Winckelmannstr 21., 42287 Wuppertal

Phone No: +49 172 2495502

Email: info@nalucanoes.com

Copyright © 2023 NALU CANOES.

📖 Impressum 📝 Terms & Conditions 🇬🇧 Privacy Policy 🇩🇪 Datenschutz

Copyright © 2023 NALU CANOES.