Menu

Tech - Material - Process

At Nalu Canoes, we believe that the art of crafting exceptional canoes is not just a process; it’s a relentless pursuit of excellence. Our canoes are a testament to the synergy of precision engineering and unwavering passion, delivering exceptional performance and reliability with every paddle stroke.

Our advanced manufacturing process, backed by computer software and technology, guarantees 100% accuracy in tooling...

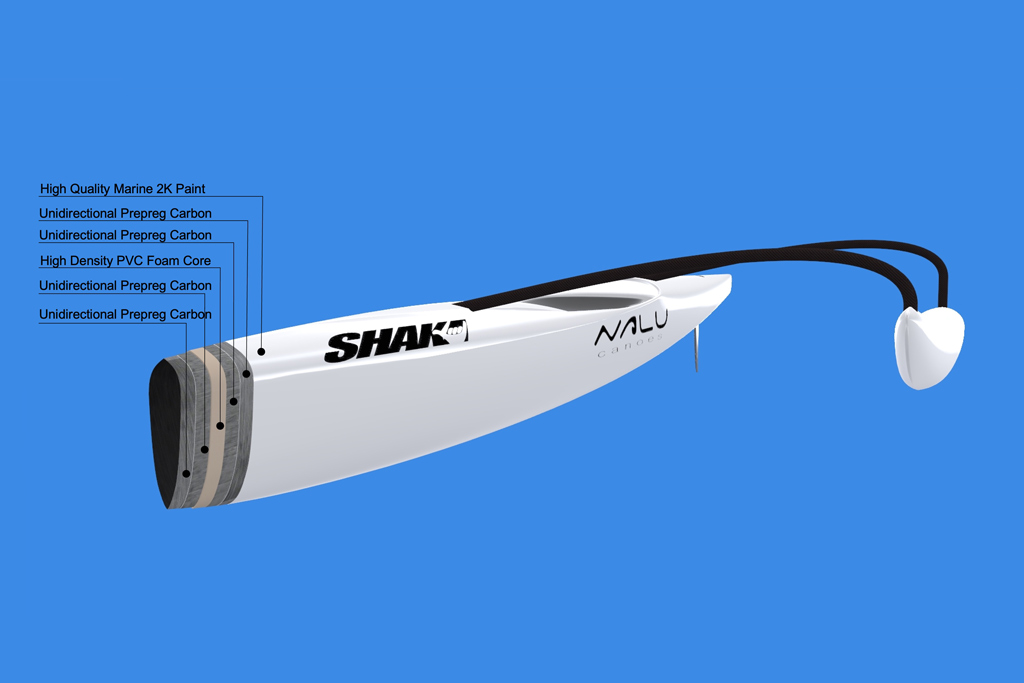

Our canoes are built using the finest materials available. We employ prepreg carbon fiber and high-density PVC foam cores...

All canoesare designed, engineered and manufactured using the latest computer software and machinery to ensure accuracy...

All canoesare designed, engineered and manufactured using the latest computer software and machinery to ensure accuracy...

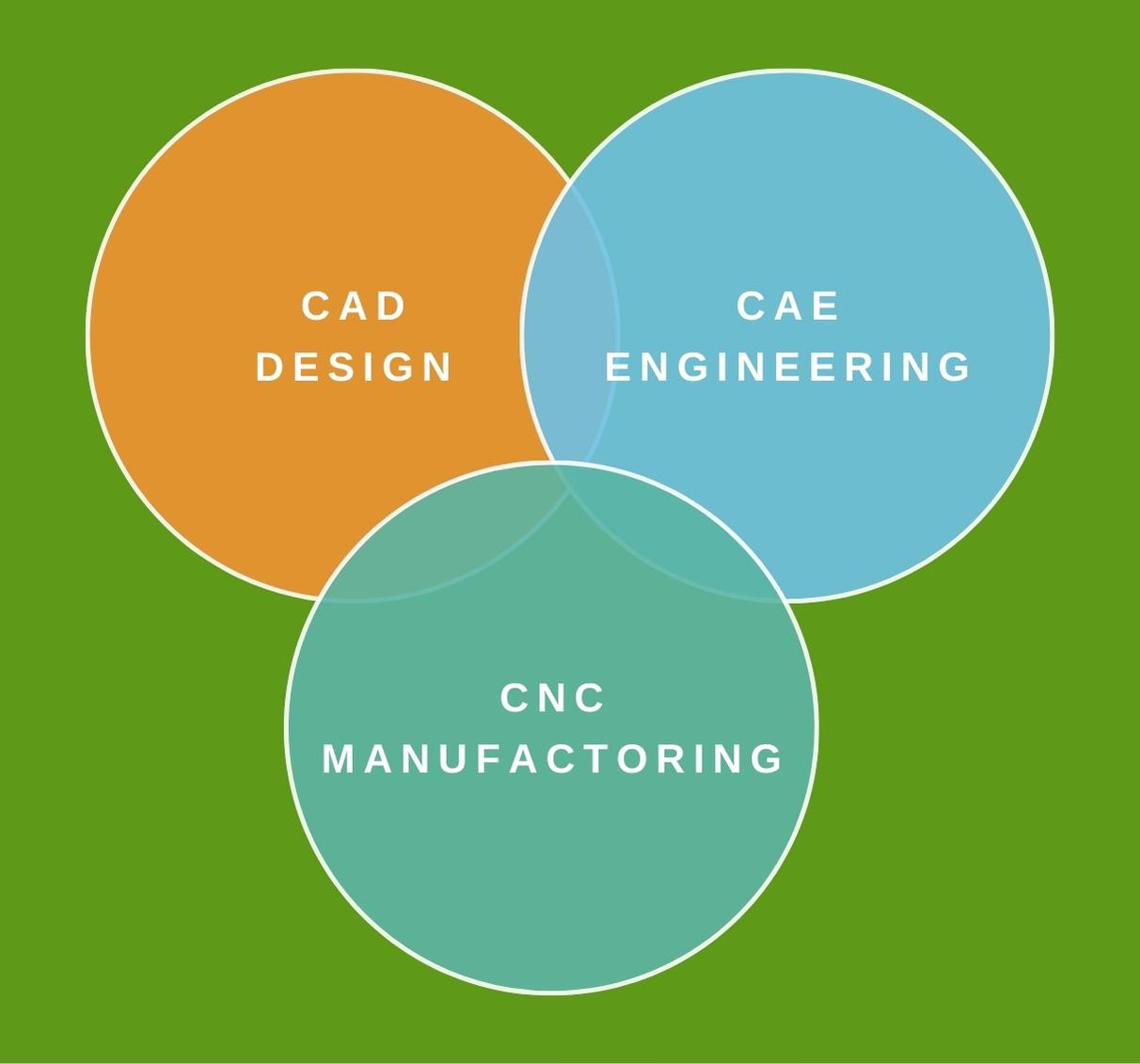

At Nalu Canoes, we are driven by the relentless pursuit of technological excellence. Our canoes are the culmination of precision engineering, state-of-the-art design, and cutting-edge technology. We employ Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) to create meticulous blueprints and simulate real-world performance. Computer Numerical Control (CNC) machining ensures every component is precisely cut to perfection. Our unwavering commitment to technology results in canoes that are at the forefront of innovation, delivering exceptional performance and reliability.

Our canoes feature unidirectional prepreg carbon fiber fabric, renowned for its non-woven structure with parallel fibers. It undergoes a meticulous resin impregnation process controlled by advanced technology. The absence of gaps and cross-weave structures ensures a maximum longitudinal tensile potential.

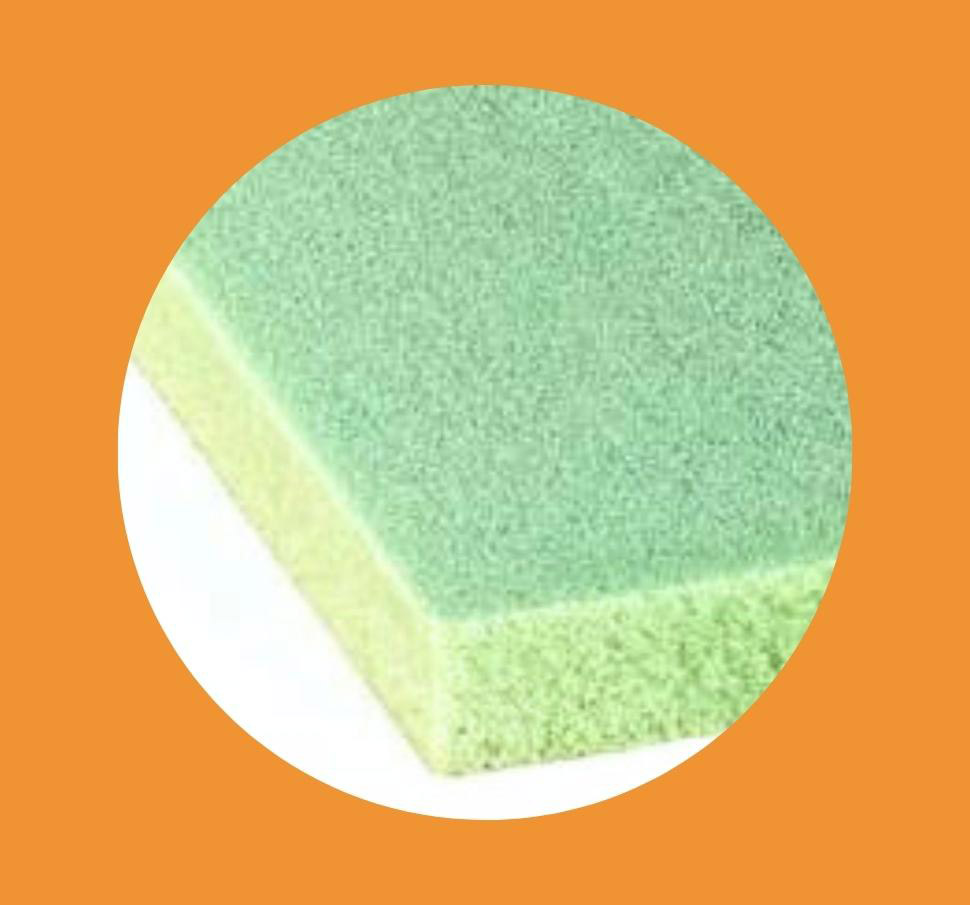

The high-density PVC foam core used in our canoes is a testament to our commitment to performance. It offers impeccable stiffness and durability while maintaining a lightweight and, It’s closed-cell structure, makes it impervious to water. It's the secret behind the perfect balance of strength and weight of our Nalu canoes.

Our canoes boast a meticulous wrapping in high-quality 2K marine paint, delivering not only 100% UV protection but also unmatched resistance to scratches and chemicals. This premium finishing touch not only preserves the canoes' aesthetics but also fortifies their functionality, guaranteeing endurance over time.

Our journey begins with CAD, where we utilize advanced software to create intricate and precise 3D models of our canoes. This digital blueprint allows us to explore and optimize every detail, ensuring the perfect synthesis of form and function before the physical production phase.

Our dedication to excellence extends to CAE engineering. Through rigorous simulations and in-depth analysis, we ensure that our canoes adhere to the most rigorous performance and durability standards. CAE allows us to evaluate structural integrity, material properties, and real-world functionality, reducing potential risks and enhancing performance.

Precision is our hallmark, and it is most exemplified through our CNC manufacturing process. This advanced technology ensures that every component is cut and shaped with the utmost precision. Controlled by computer programs, CNC machining guarantees consistent and accurate cuts, allowing for the creation of intricate geometries and unparalleled precision.

Our journey begins with CAD, where we utilize advanced software to create intricate and precise 3D models of our canoes. This digital blueprint allows us to explore and optimize every detail, ensuring the perfect synthesis of form and function before the physical production phase.

Our dedication to excellence extends to CAE engineering. Through rigorous simulations and in-depth analysis, we ensure that our canoes adhere to the most rigorous performance and durability standards. CAE allows us to evaluate structural integrity, material properties, and real-world functionality, reducing potential risks and enhancing performance.

Precision is our hallmark, and it is most exemplified through our CNC manufacturing process. This advanced technology ensures that every component is cut and shaped with the utmost precision. Controlled by computer programs, CNC machining guarantees consistent and accurate cuts, allowing for the creation of intricate geometries and unparalleled precision.

Prior to assembly, our materials undergo a journey of precision. Computer-controlled cutting machines meticulously pre-cut all materials, ensuring a perfect fit in every component. This step is where technology meets craftsmanship, guaranteeing that each piece aligns seamlessly in the creation of your canoe.

After lamination, the canoe molds are subjected to the meticulous process of vacuum-bagging. Placed within autoclaves, they experience three times atmospheric pressure and heat. This treatment results in a superior bonding between layers, culminating in a canoe that is light, robust, and reliable.

Stay updated with the latest happenings in the world of outrigger canoes. Dive into our News section for insightful articles, product updates, and exciting stories that inspire your waterborne adventures.

Join our canoe community and never miss an update. Subscribe to our newsletter for exclusive insights, special offers, and news. Be the first to know, and stay connected with Nalu Canoes.

OC1 OC2 Outrigger Canoes

NALU CANOES Germany

Winckelmannstr 21., 42287 Wuppertal

Phone No: +49 172 2495502

Email: info@nalucanoes.com

OC1 OC2 Outrigger Canoes

NALU CANOES Germany

Winckelmannstr 21., 42287 Wuppertal

Phone No: +49 172 2495502

Email: info@nalucanoes.com

Copyright © 2023 NALU CANOES.

📖 Impressum 📝 Terms & Conditions 🇬🇧 Privacy Policy 🇩🇪 Datenschutz

Copyright © 2023 NALU CANOES.